LaserEMobility

Digital and sustainable laser-based manufacturing for next generation electric mobility

LASEREMOBILITY WORKSHOP 2024

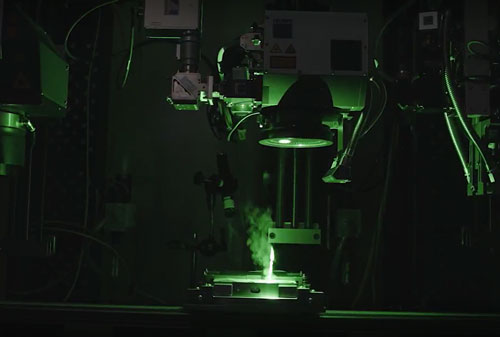

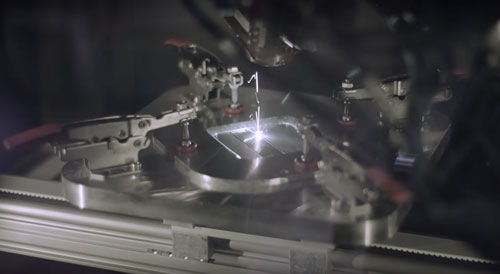

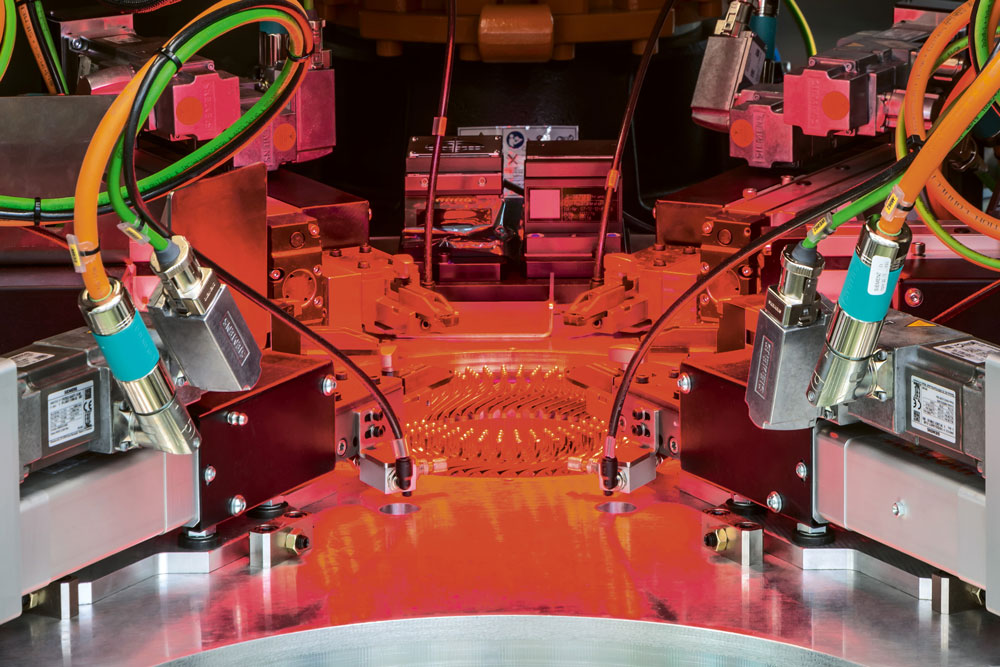

Lasers, as flexible digital tools, are widely used in the production of electric vehicles. Newly designed products incorporate various laser-based manufacturing processes, such as welding, cutting, surface texturing, and heat treatment. LaserEMobility is working to promote laser technologies in electric vehicle production by creating a network of universities and industrial companies.

KEYWORDS

E-mobility

Laser based manufacturing

E-drives

Battery

Mission

LaserEMobility aims to gather and share knowledge in the field through various initiatives such as the LaserEMobility Workshop. The section seeks to address the ongoing demand from industry for laser technologies and the growing academic collaboration. This section focuses on questions related to electric propulsion and energy storage systems in electric vehicles.

- Digitalization of the processes and the products in laser-based manufacturing for e-mobility

- Standardization of the processing conditions and testing of the process performance

- Sustainability and resource usage in laser processes for e-mobility

- Knowledge transfer from novel beam shaping and process diagnostics approaches to industrial process solutions

The main products and systems of interest are the electric drives, battery systems, fuel cells, power electronics, and their peripheral systems. The section aims to establish a network of laser-based manufacturing specialists and users that can extend their knowledge in the future challenges also beyond electric mobility.

- Lasers provide the digital tools for the next generation mobility.

- Digital and sustainable manufacturing enabled by lasers.

- Integrating digital and physical worlds for a robust laser based manufacturing in e-mobility.

Coordinatori e componenti fondatori

Rubin Corbinelli

Coordinatore accademico

IMA Automation Atop Spa

Alessandro Fortunato, Alma Mater Studiorum Università di Bologna

Fabian Vieltorf, Institute of Machine Tools and Industrial Management iwb, Technische Universität München

Michael Schmidt, Friedrich-Alexander-Universität

Luca Di Silvio, Manz Italia

Wolfgang Lehmann, Raylase