ADAPT

ADAptive manufacturing processes for elongated Profiles and seam welded Tubes.

ADAPT responds to the need for flexibility and integration in the manufacturing supply chain of profiles and welded tubes. It proposes the implementation of adaptive in-line control systems and methodologies based on Digital Twin approaches, FEM, and Artificial Intelligence to achieve 'First Time Right' production.

KEYWORDS

Tube;

Roll forming;

Bending;

Adaptive Manufacturing;

Industry 4.0

Mission

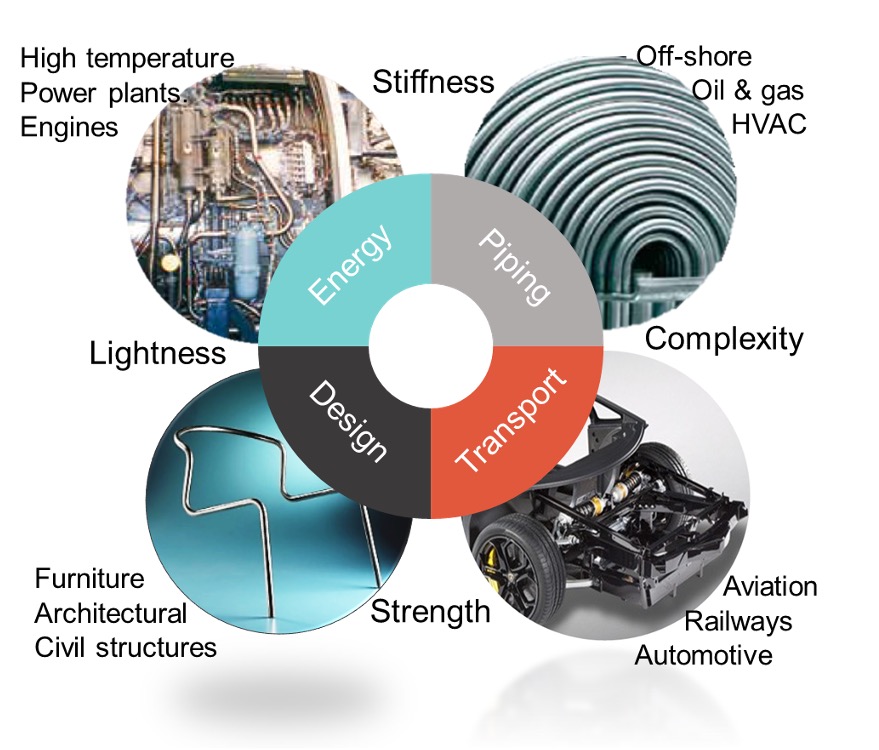

The ADAPT Section operates in a highly technological and competitive sector, characterized by the processing of metallic profiles and tubes. This field requires continuous innovation and the application of new technologies to meet the demand for high quality, process automation, and integration of different production entities. In the modern industrial context, one of the biggest challenge lies in increasing the flexibility of production processes while maintaining high levels of productivity and efficiency.

The ADAPT Section aims to meet these challenges through the implementation of in-line process control logic taking also into account the supply chain. The main goal is to improve product quality, reduce tooling and setup times and costs, and minimize scraps. The specific areas of focus include:

- Sensing and Monitoring: Implementation of advanced sensors for real-time monitoring of process parameters, allowing for more accurate and timely control.

- Automation and Flexibility: Design and architecture of innovative equipment to ensure greater automation and flexibility in production processes.

- In-Line Control: Development of advanced algorithms for in-line process control.

- Digital Twin, AI, and Modeling: Use of Digital Twin and AI techniques for the development of advanced process models that enable real-time simulation and optimization of processes.

- Traceability and Quality: Improvement of component traceability and their properties along the supply chain.

ADAPT is committed to discussing solutions for the implementation of advanced systems, today available at laboratory-scale, that can meet the needs of the industrial sector. With particular attention to an integrated approach along the supply chain, with the intent to guide innovation and promote sustainable development in the manufacturing industry.

- Focus on Innovation: "Development of flexible processes in the production of metal profiles."

- Quality and Technology: "Use of Digital Twin and AI to optimize process efficiency."

- Production Efficiency: "Reduction of production costs through advanced process control."

Coordinatori e componenti fondatori

Carlo Betetto, Gasparini s.p.a.

Andrea Costa, Condevo spa

Antonio Fiorentino, Università degli Studi di Brescia

Tommaso Mancia, Università Politecnica delle Marche

Michele Parise, Ricos srl

Matteo Strano, Politecnico di Milano