Realize

Surface treatment and functionalization

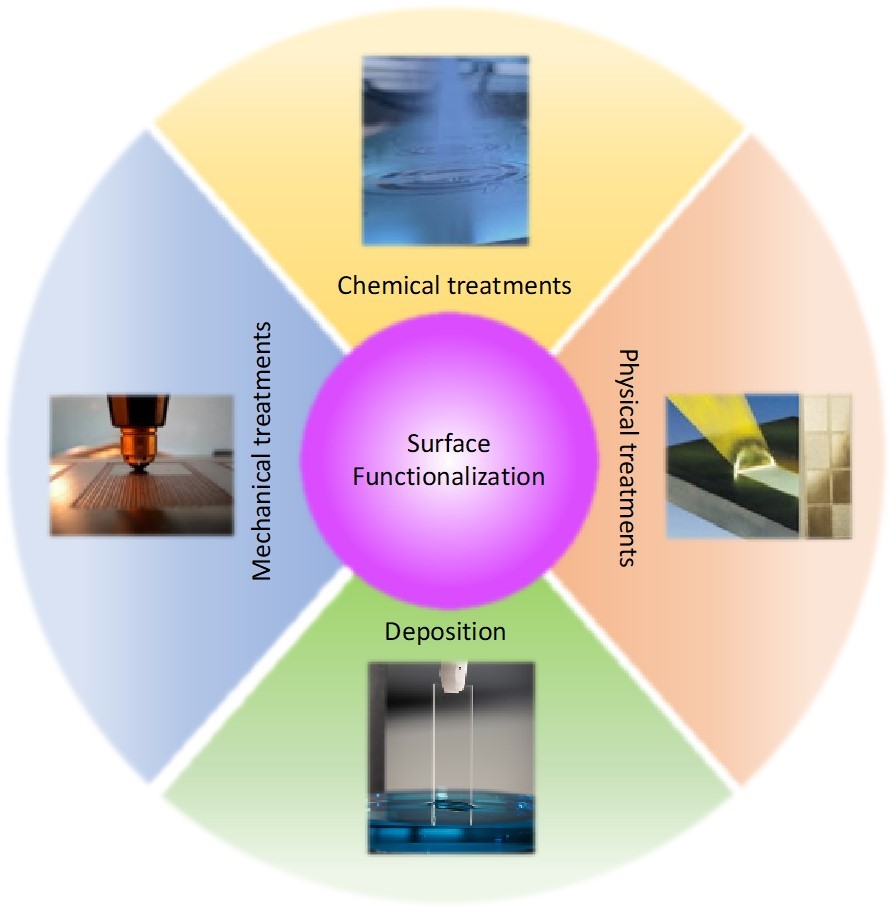

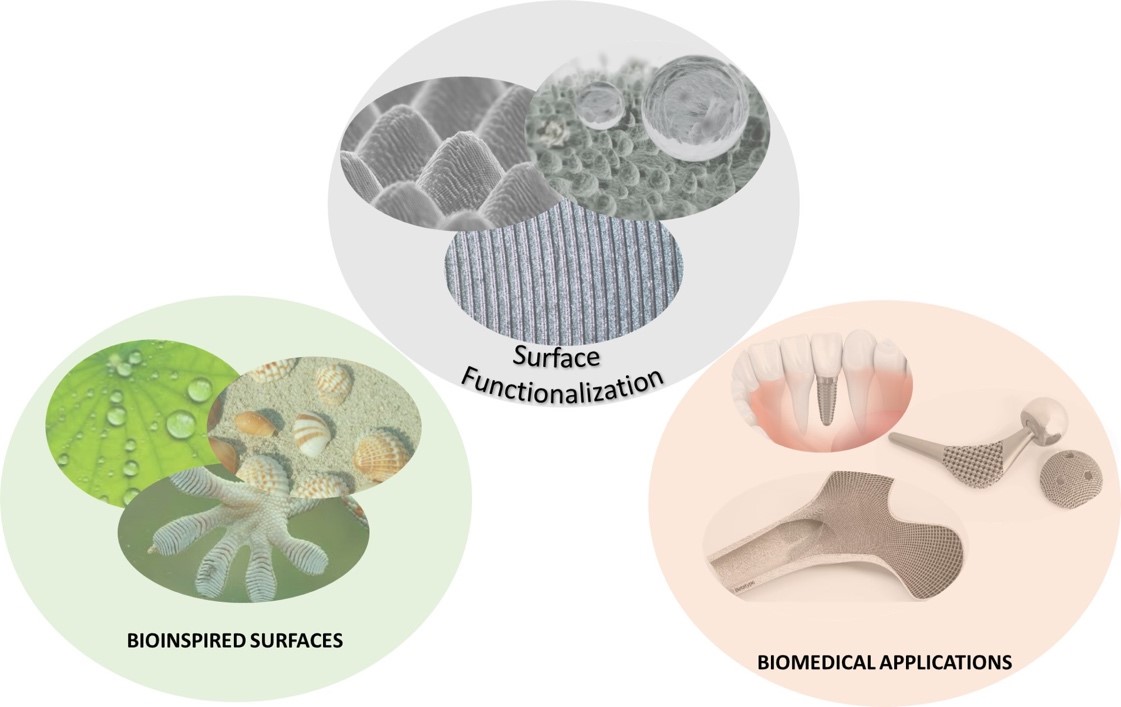

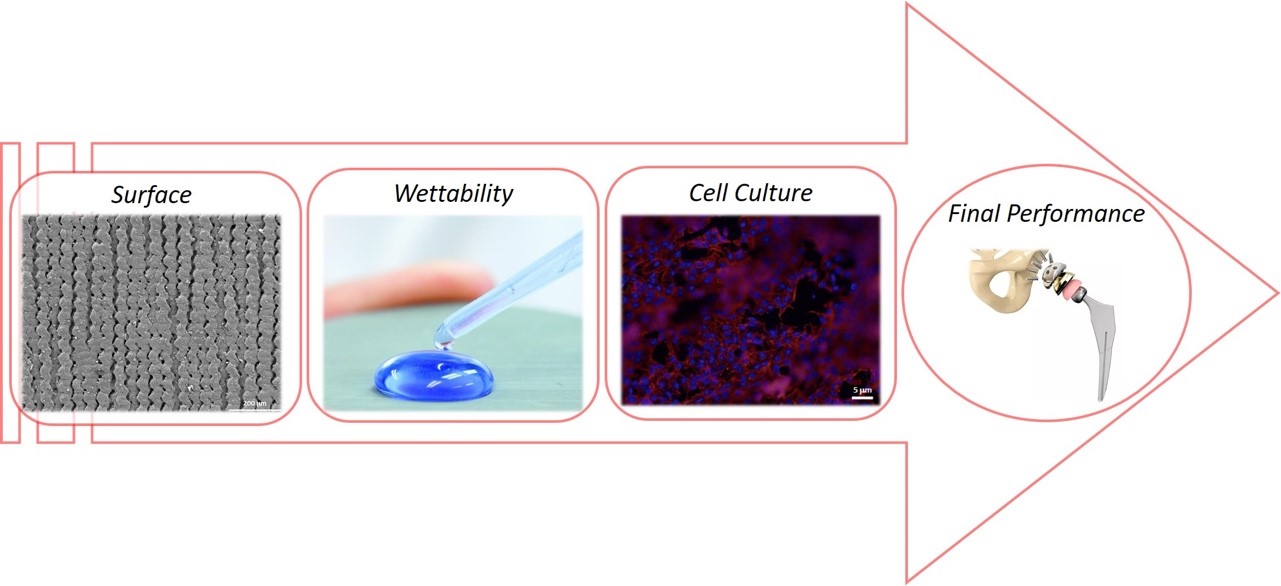

Surface characteristics dictate components’ performance and functionalities by modification processes able to locally modify the surfaces giving properties that the bulk material does not naturally possess. Realize collects technical and industrial know-how to manufacture biomedical products featured with effective surface modifications improving the overall product performance (e.g., burnishing, turning, peening, sand blasting, etching, and laser texturing).

KEYWORDS

Functionalization

Surface treatments

Post processing

Functionally graded materials

Mission

Realize jointly works with academy and industries to support the development and the application of surface treatment manufacturing and surface functionalization techniques in the field of biomedical applications. The surface state of components for different applications often determines their performance and functionality. It therefore requires the possibility of locally modifying the surfaces of some products to confer properties that, normally, the base material does not possess. This process, known as functionalization, attracts enormous scientific and industrial interest. Appropriately modifying the surface of the material represents a unique tool for attributing new properties to traditional materials: it extends the field of use, allowing a wide range of additional functions to be obtained, compensating for the deficiencies of the starting material and maintaining, at the same time, its peculiar properties at the bulk level. Consequently, the functionalization of surfaces has become crucial for academic research and for the development of industrial products whose use in the technical field is potentially infinite.

Realize aims to study and characterize the surface functionalization techniques, training companies on existing processes, supporting them in choosing the most suitable technology for improving the surface characteristics of their products. It will focus on a specific family of surface functionalization techniques for the production of biomedical products, typically bone plates and fixation devices. Among these techniques the following will be deeply analyzed:

- Functionalization through plastic deformation processes (burnishing, turning, peening, etc.);

- Functionalization by chemical etching;

- Functionalization by laser texturing.

- "Funzionalizzare efficacemente le superfici in ambito biomedicale rappresenta una sfida ancora aperta"

- "Superfici ottimizzate ottenute mediante funzionalizzazione migliorano le performance dei prodotti"

- "Fabbricare superfici complesse consente di modularne l’interazione con l’ambiente esterno"

Coordinatori e componenti fondatori

Franzese Giorgio

Coordinatore industriale

Italbacolor srl

Rotella Giovanna, Università LUM Giuseppe Degennaro, Dipartimento di Management,

Finanza e Tecnologia

Vinci Angelo Michele, Masmec spa

Filice Luigino, Università della Calabria, Dipartimento di Ingegneria Meccanica, Energetica e Gestionale

Carlone Pierpaolo, Università del Salerno, Dipartimento di Ingegneria Industriale

Romoli Luca, Università di Pisa, Ingegneria Civile e Industriale

Rubino Felice, University of Rey Juan Carlos, Madrid

Basile Vito, STIIMA-CNR

Franzese Giorgio, Italbacolor srl

Tatullo Marco, Marrelli health srl

Iaquinta Mario, Poliedrica srl

Binetti Sergio, Binetti Macchine Utensili srl

è disponibile il white paper della sezione al link:

https://link.springer.com/chapter/10.1007/978-3-031-41163-2_15