SIMPCo

Sustainable and Innovative Manufacturing Processes for Composites

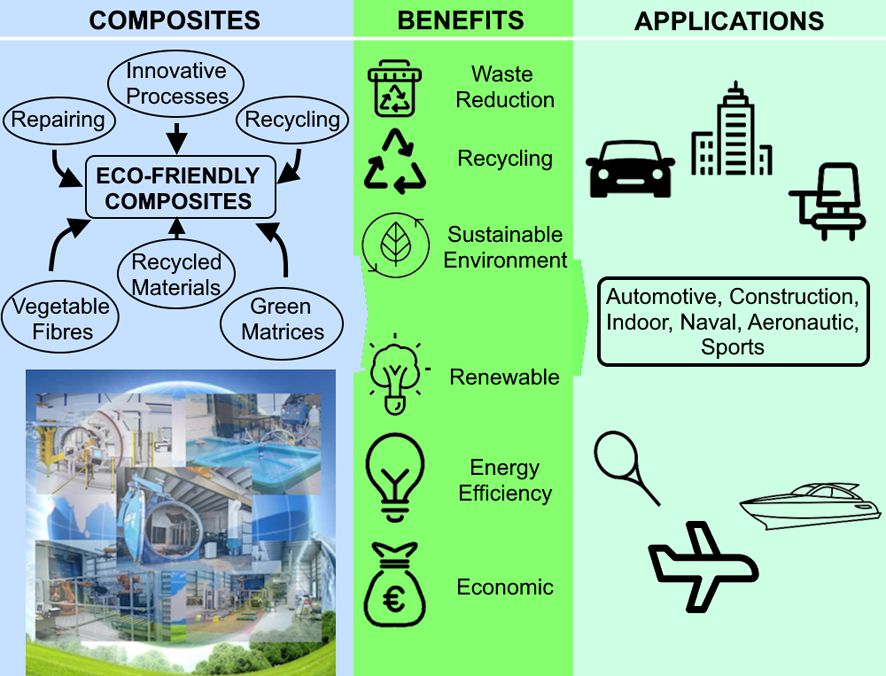

In the context of the green revolution we are all involved in, the SIMPCo section aims to address, explore, and disseminate developments focused on new innovative production and recycling technologies of composite materials. It promotes a more environmentally sustainable approach, both in terms of product and process, in line with the current demands of the international manufacturing sector.

KEYWORDS

Green-Composite materials;

Innovative manufacturing processes;

Repairing processes;

Recycling processes;

Circular economy

Mission

The SIMPCo section arises from the need to delve into, disseminate, and promote the innovative and sustainable development of fiber-reinforced polymer (FRP) composites. In a context where the demand for FRPs is consistently growing across various industrial sectors, the section commits to playing a key role in scientific advancements related to both production processes and utilized materials.

To serve as a bridge between academic research and industry, SIMPCo aims to explore and disseminate technological innovations that can enhance environmental sustainability, automation, and monitoring of FRPs production processes. Additionally, it focuses on new technologies for recycling and repairing with low environmental impact, aligning with the global trend towards adopting principles of the circular economy. Moreover, at the core of the section is the study and the rational selection of starting materials for the production of more sustainable products, with a focus on materials with a lower environmental impact and of the new generation (such as 'green' materials) including vegetable fibers, and eco-friendly matrices (both thermoplastics and thermosetting) and recycled products. In a synergistic manner, the significant issue of how the entire production cycle is influenced by the adoption of these new materials will be explored and studied.

Overall, the mission of SIMPCo is to create a network among universities and industries that work in the composite manufacturing field, addressing developments centered around the use of new materials and innovative production and recycling technologies. It aims to promote greater environmental sustainability and facilitate the technology transfer to industry through training activities.

- "Processi innovativi e green-materials: il futuro sostenibile dei compositi"

- "Advanced Research for Future FRPs: Reduce, Recycle and Repair"

- "Process Tuning and Characterization of FRPs"

Coordinatori e componenti fondatori

Giuseppe De Tommaso

Coordinatore industriale

ATM (Advanced Tools and Mouldes) SRL

Pierpaolo Carlone, Università degli Studi di Salerno

Massimo Durante, Università degli Studi di Napoli Federico II

Lorenzo Donati, Università di Bologna

Luca Raimondi, Università di Bologna

Antonio Langella, Università degli Studi di Napoli Federico II

Valentina Lopresto, Università degli Studi di Napoli Federico II

Michela Simoncini, Università Politecnica delle Marche

Loredana Santo, Università degli studi di Roma Tor Vergata

Luca Sorrentino, Università degli Studi di Cassino e del Lazio Meridionale

Fausto Tucci, Università degli Studi di Salerno

Sisto Fini, Tecnologie Avanzate di Veroli

Guido Fini, Tecnavan Interiors di Castelli